Smart and fast production planning for manufacturing

Coortex Seed APS synchronizes your factory, optimizes resources, and ensures on-time deliveries. Advanced scheduling software built for plastics, food & beverage, steel, and auto parts industries.

Coortex Seed APS synchronizes your factory, optimizes resources, and ensures on-time deliveries. Advanced scheduling software built for plastics, food & beverage, steel, and auto parts industries.

Our APS software solves the unique complex scheduling challenges of your specific industry.

Optimize mold changes, machine setup times, and complex injection cycles.

Manage shelf life restrictions, recipe combinations, and washdown sequencing.

Handle continuous casting processes, routing constraints, and heat optimization.

Synchronize assembly lines, manage JIT deliveries, and component inventory.

The modern APS solution for complex Industry 4.0 challenges.

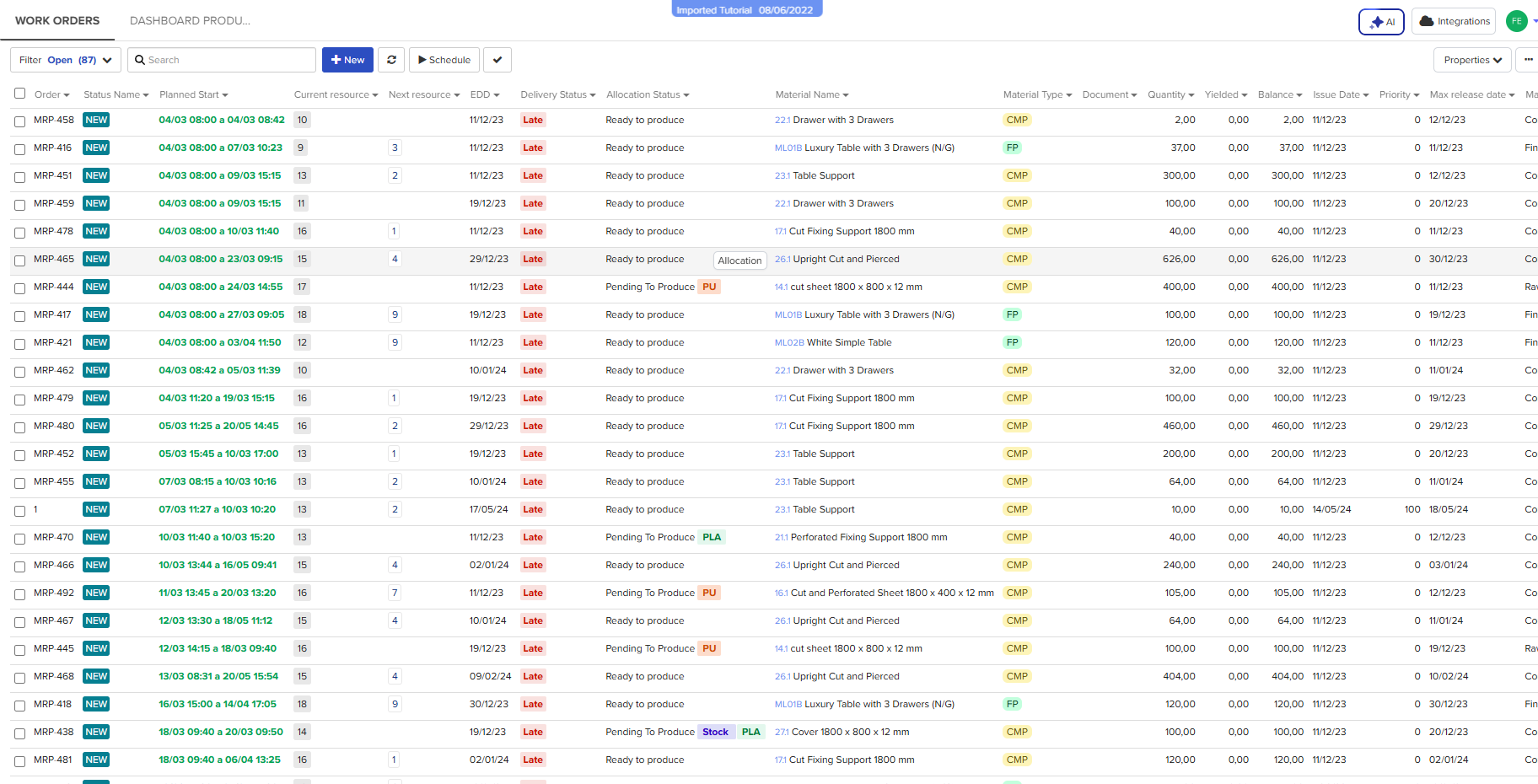

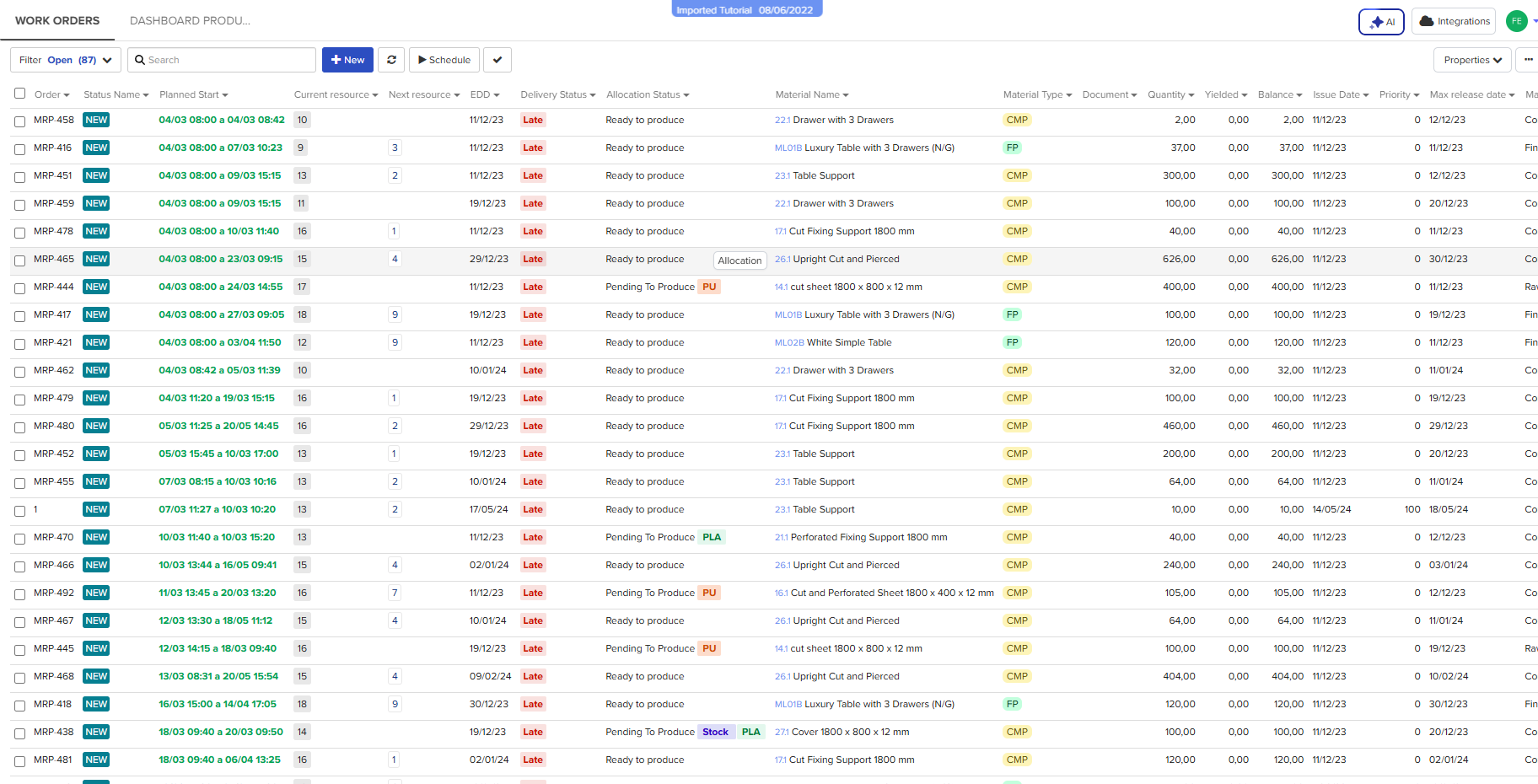

React instantly to unforeseen events like machine breakdowns or material shortages and reschedule in seconds.

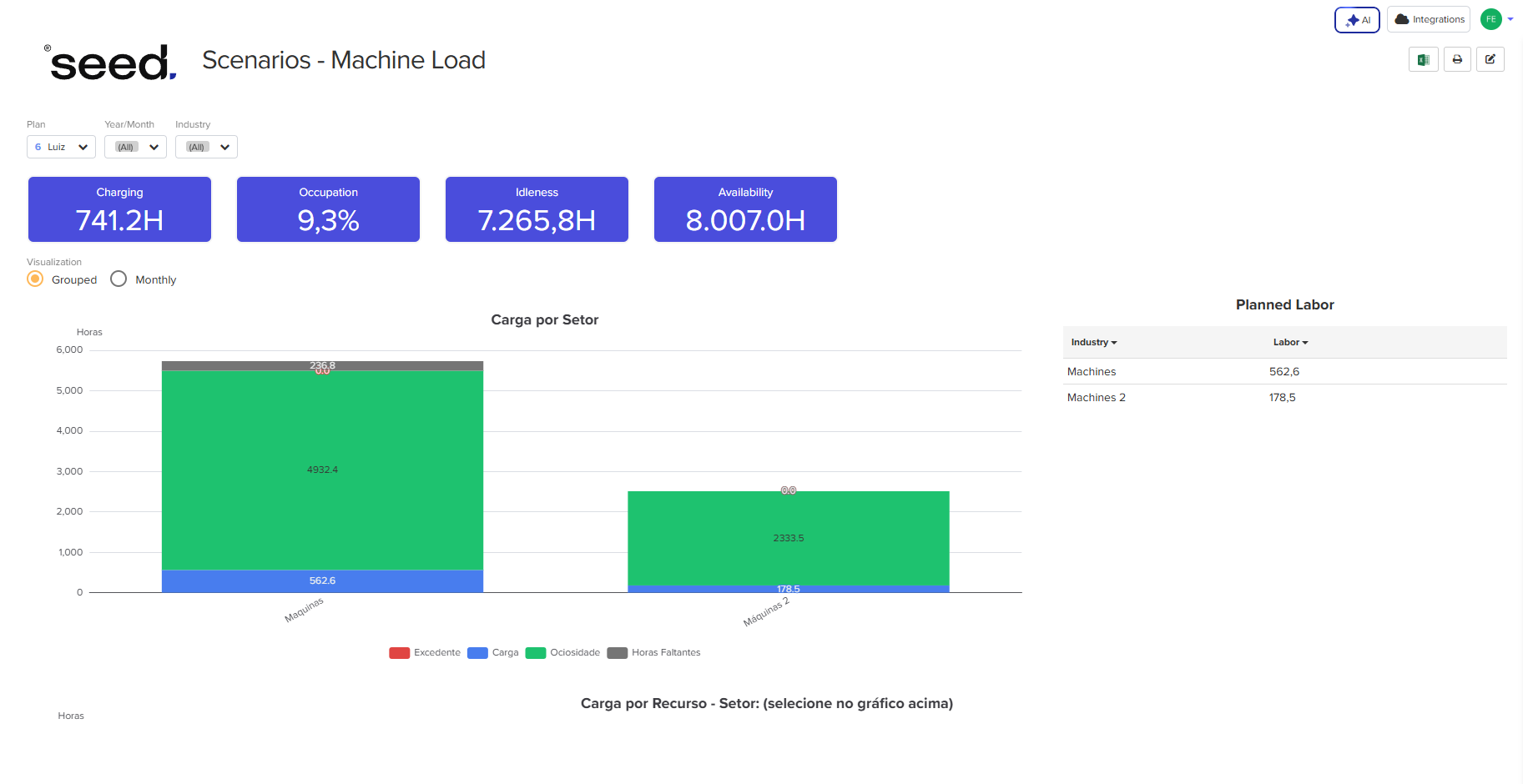

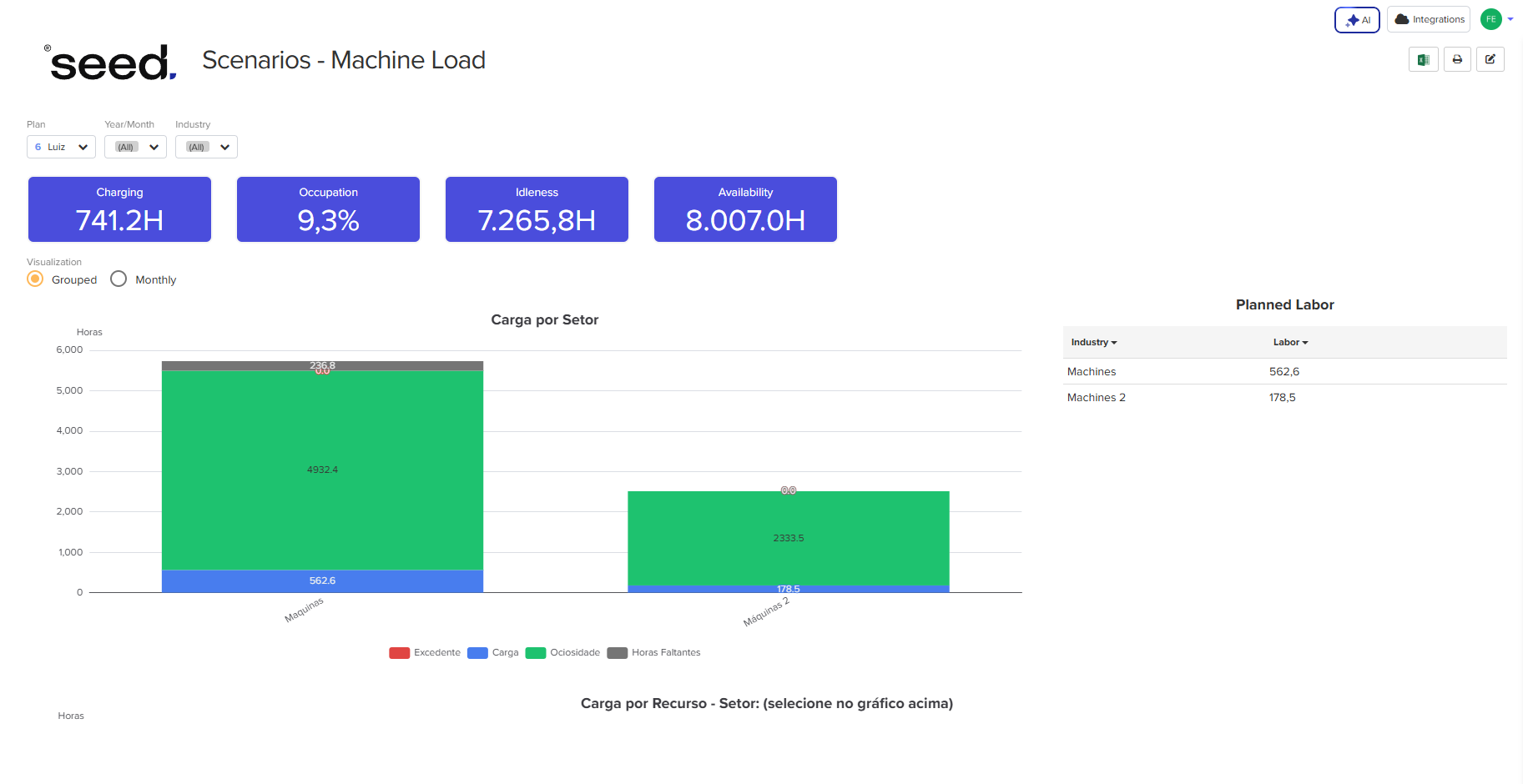

Maximize bottleneck utilization and balance workloads across machines and operators automatically.

Use CTP (Capable-to-Promise) to provide realistic delivery dates based on current factory capacity.

A complete ecosystem for your factory, connecting strategy to shop floor execution.

Align strategic goals with production capacity and market demand.

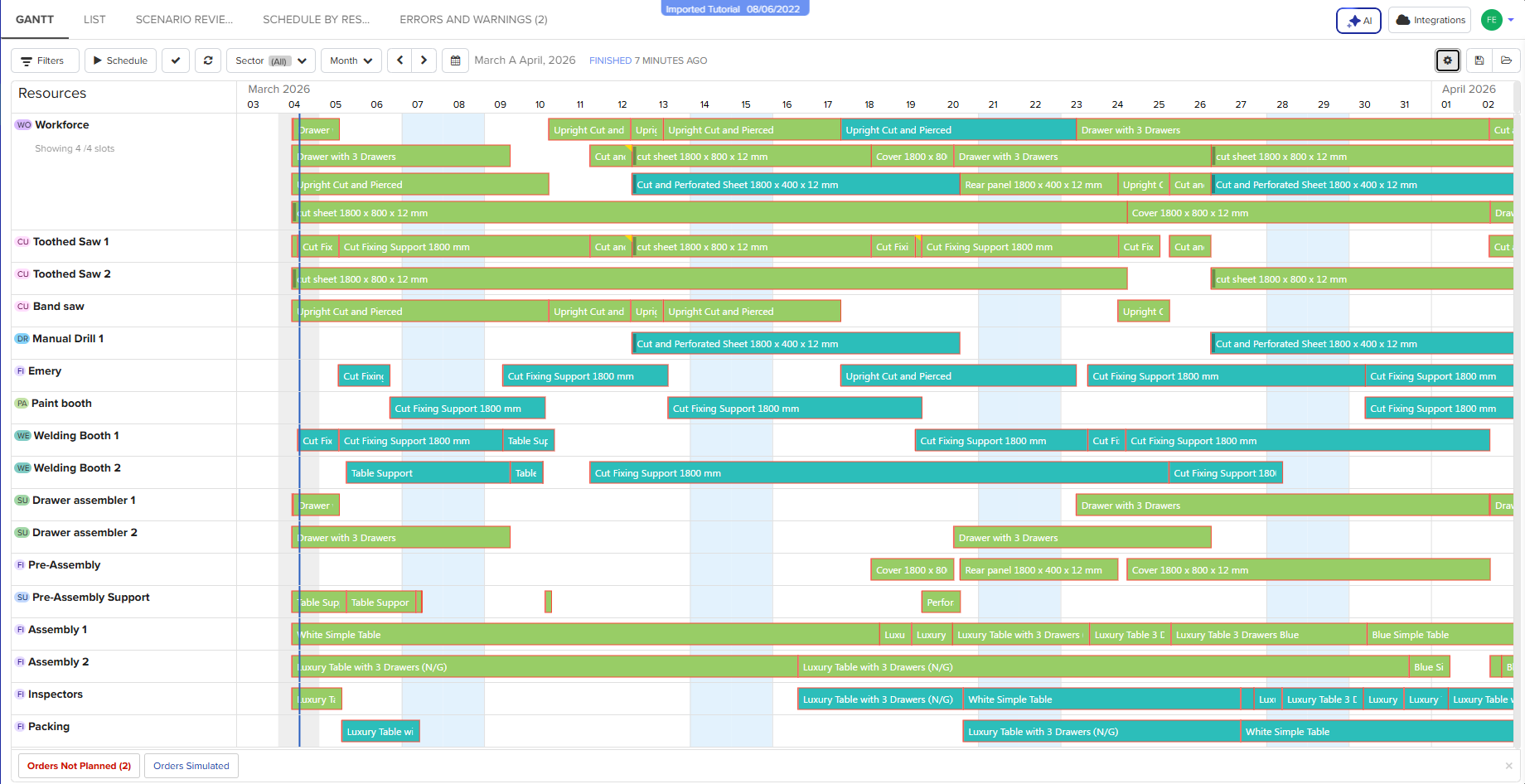

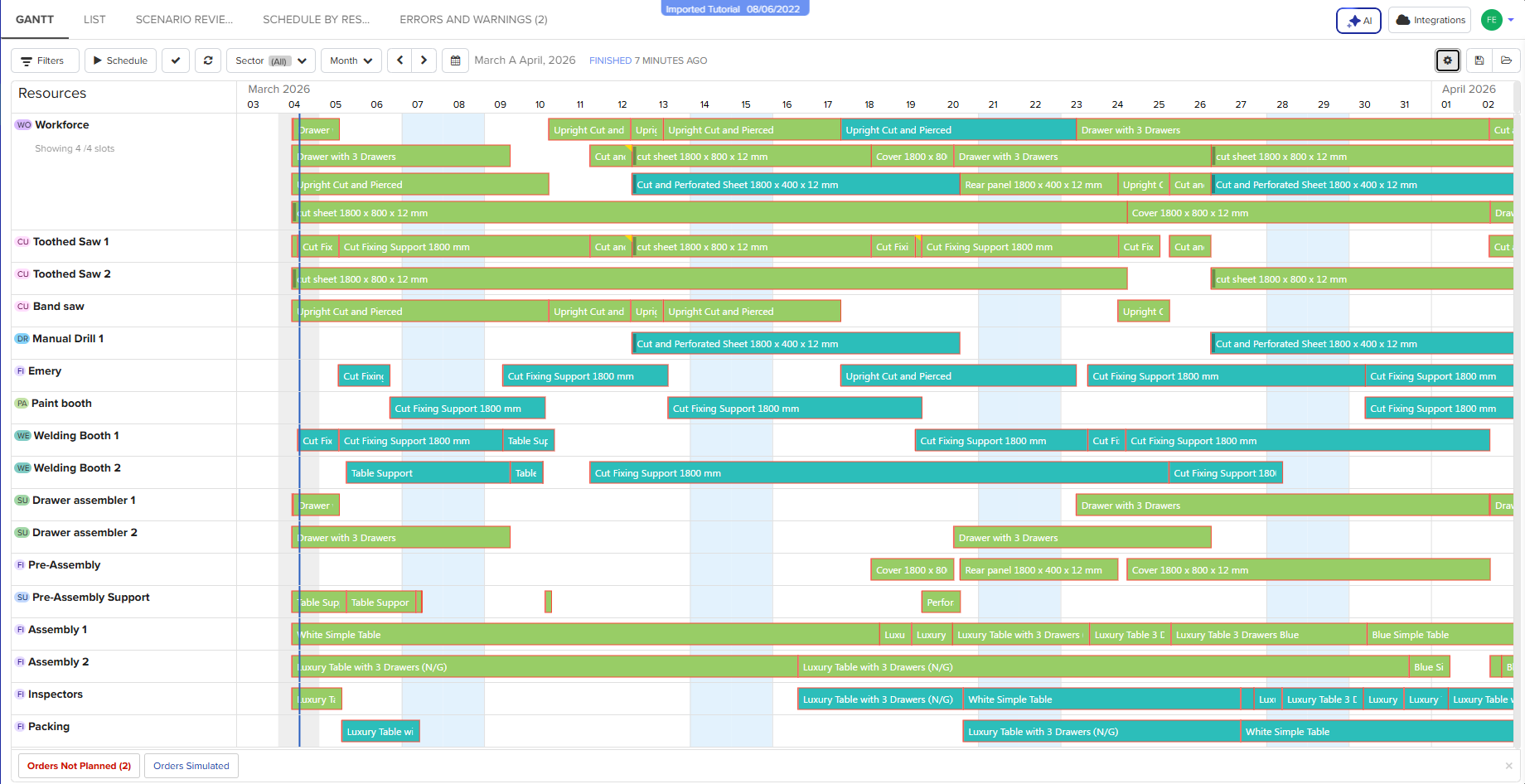

Connect strategic planning to real-time execution on the shop floor.

Ensure material availability for production while maintaining low inventory levels.

Generate optimized production sequences considering constraints, setups, and priorities.

Gain real-time visibility into factory performance with interactive metrics.

Easily connect to your ERP and generate detailed insights for data-driven decisions.

Schedule a personalized demo and see how Coortex Seed APS can increase efficiency and reduce costs.

Request Demo